Austin TX · with TwoPlus Collaborative · 2018

“Mirror Cloud” increases appreciation of the natural world by literally reflecting the immediate surroundings in a series of mirrors that juxtapose and collage information, creating an unexpected reading of familiar context. The piece is constructed out of two-sided mirror-finish stainless steel, bent into hollow triangular volumes and suspended on a steel frame. Due to their hollow nature, the mirrors act in duality - from a distance, the mirrors reflect the nearby trees, ground, sky, and visitors in the vertical surfaces. Up close, the mirrors kaleidoscopically reflect the sky above in the triangular interiors of each volume.

The intent behind the piece is to intensify the visitor’s understanding of place, heightening awareness of the immediate environment by presenting it in a new way, while allowing individuals to see themselves as a part of the landscape in the mirror reflection. Located along a public and active trail, the piece seeks to engage visitors and passerby in an immersive experience that invites deeper observation and perception of the natural world.

“Mirror Cloud” was commissioned along with 9 other pieces by the City of Austin’s Art In Public Places program as part of the TEMPO 2018 exhibition. The piece was installed for two months at the Austin Nature and Science Center before moving to Festival Beach along Lady Bird Lake for two weeks. TwoPlus Collaborative was responsible for the design, fabrication and installation of the piece at the two different locations.

PROCESS

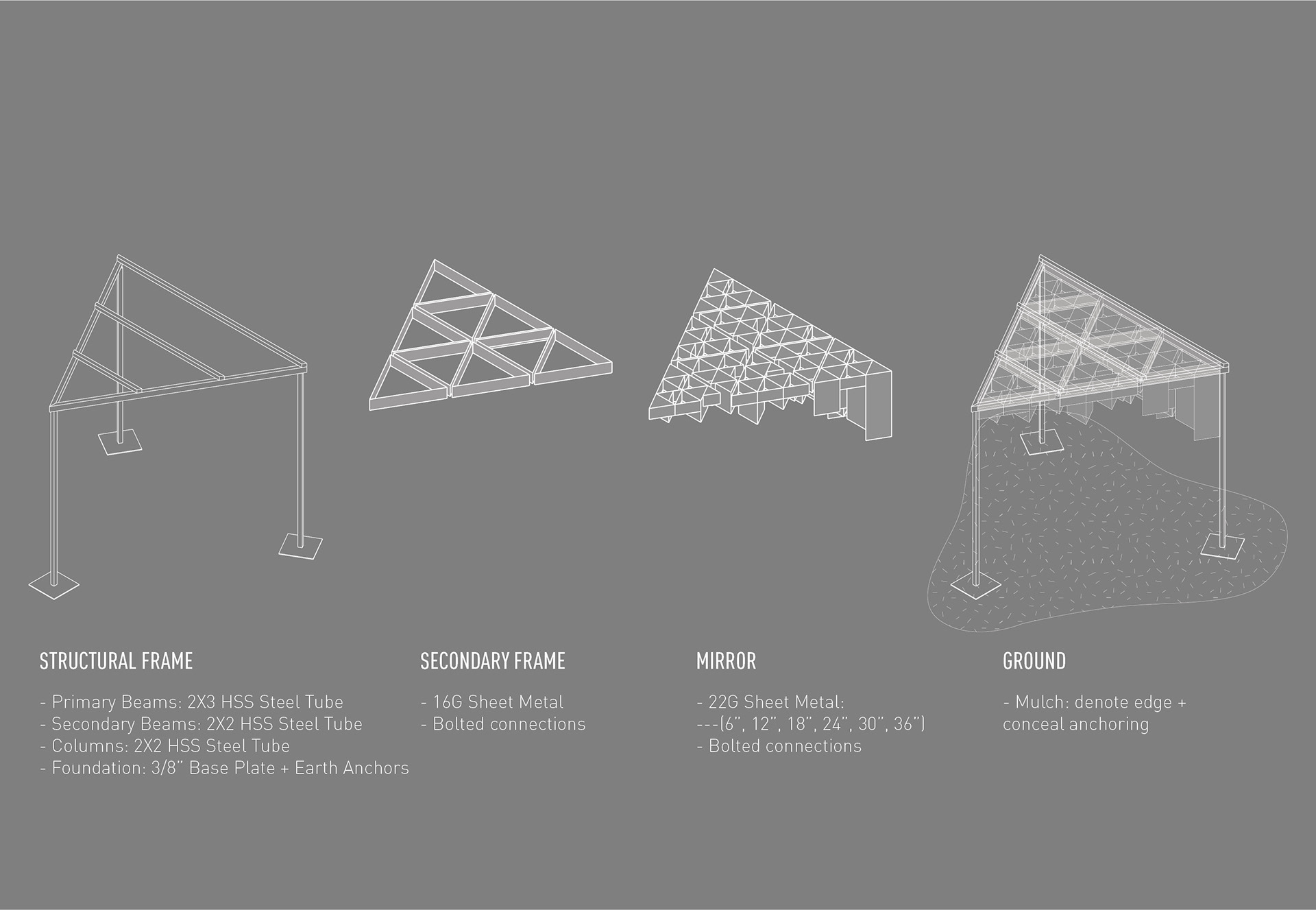

DESIGN: We began with a helpful material constraint - we wanted to re-use the 8’ tall mirror triangles from our previous project, “Blind Spot”. Through sketching and modeling, we established a proportional and structural strategy to enable the mirrors to float above the ground, creating an occupiable zone below. This formed the basis of the proposal submitted to AIPP. Once selected, we worked with AIPP to refine our ideas and address the immediate context of the site we were given.

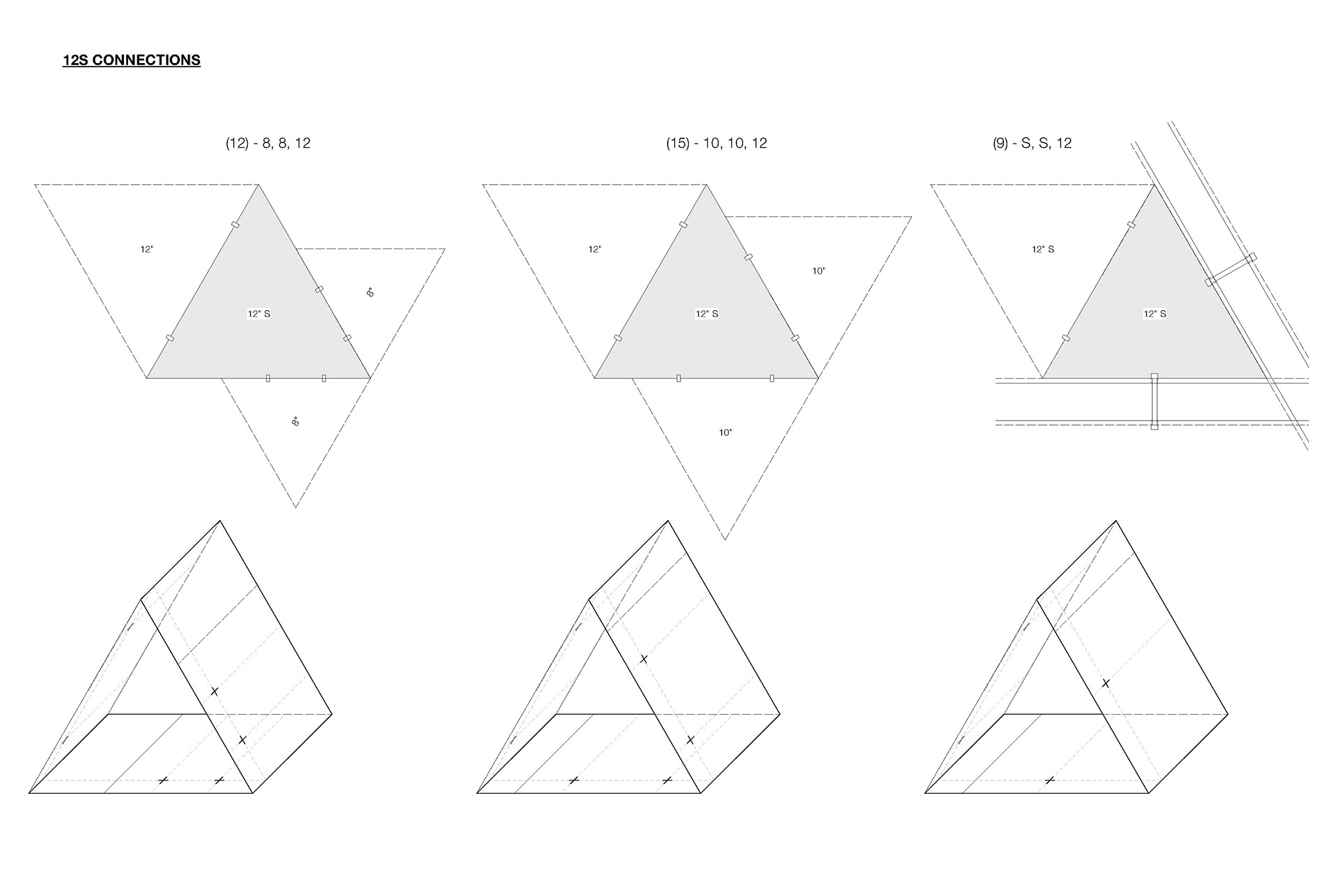

FABRICATION: The first step was to cut the stainless steel mirrors into the desired lengths. Armed with a jigsaw, this part proved particularly arduous but things picked up speed after that. We then assembled the mirror sections into 9 pre-fabricated triangular modules, each containing 9 triangular sections, held together with tiny stainless bolts. We collaborated with Adam Tablemaker (adamtablemaker.com) to design and fabricate the steel structure which supports the hanging mirrors.